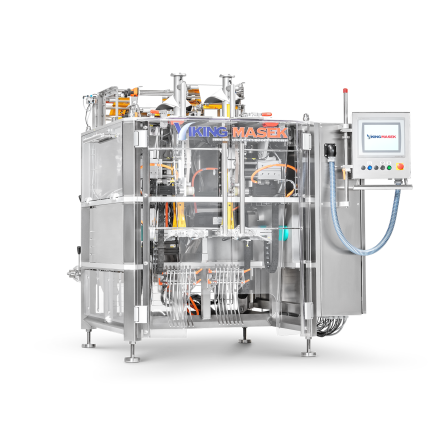

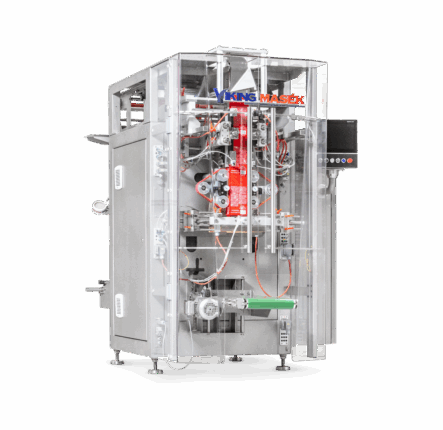

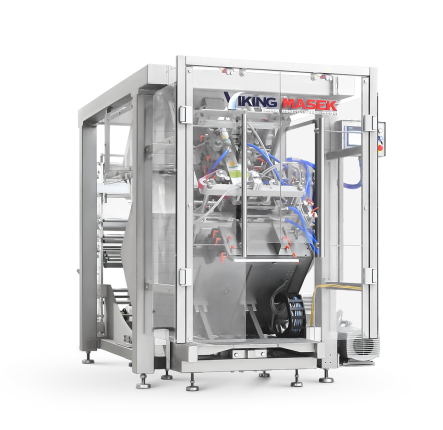

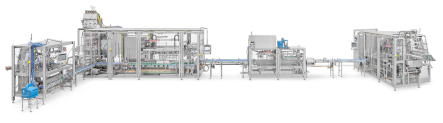

Every product is packaged perfectly thanks to its efficient and reliable design.

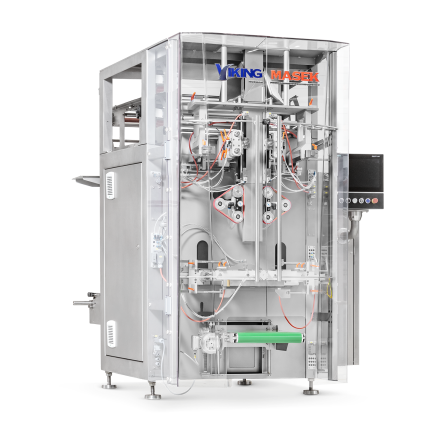

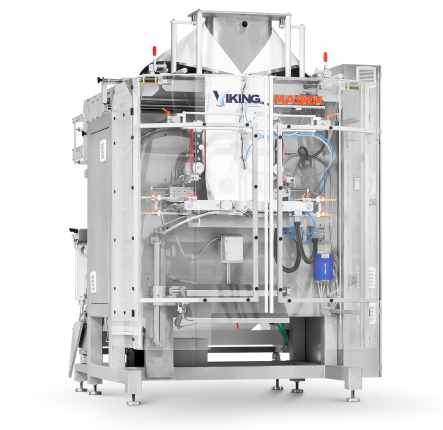

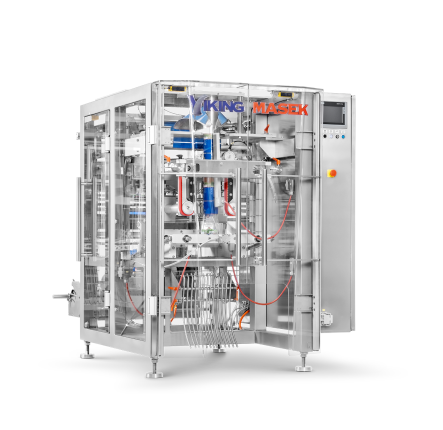

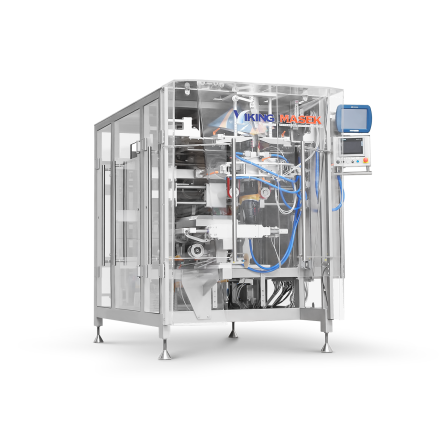

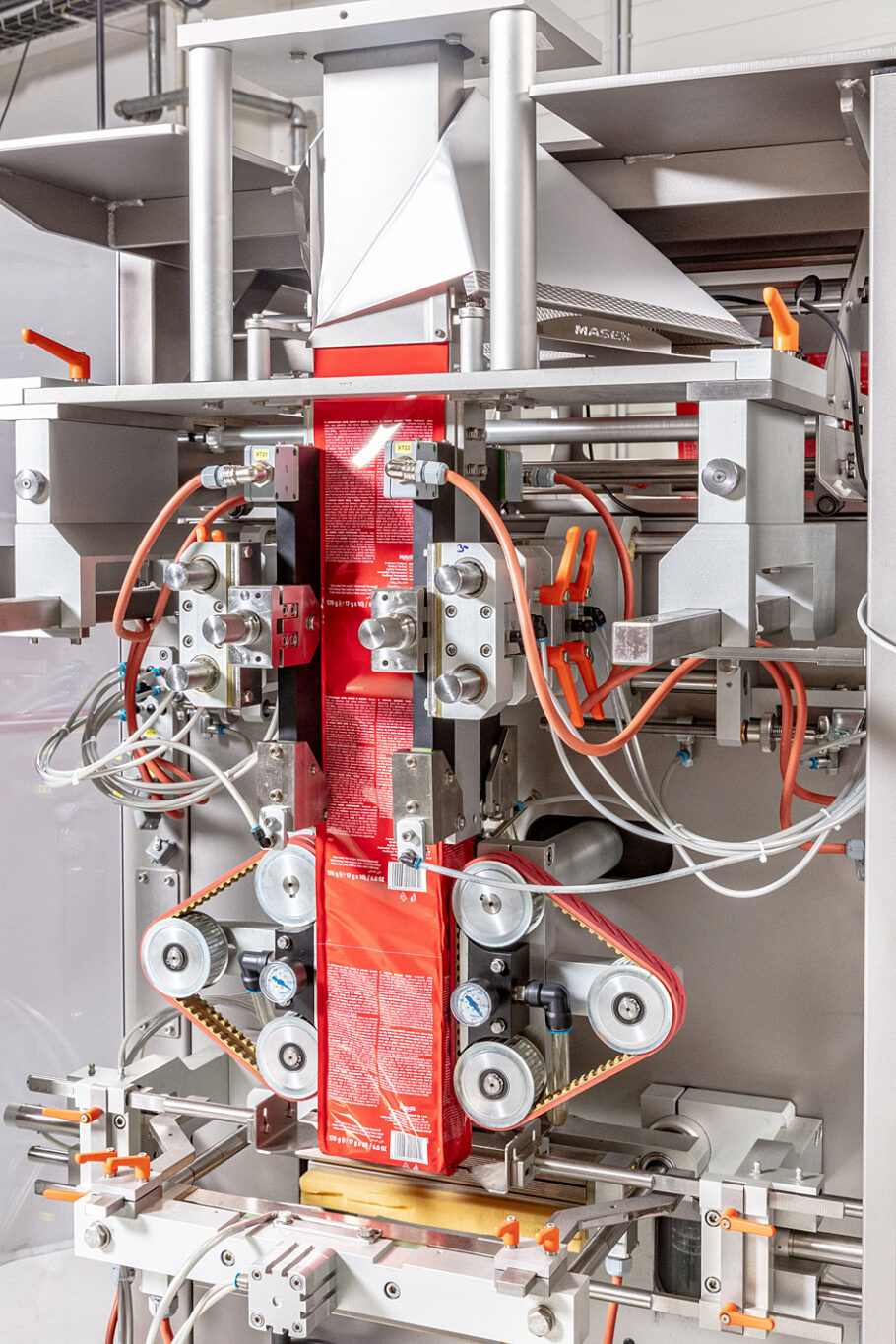

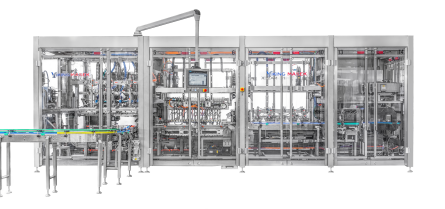

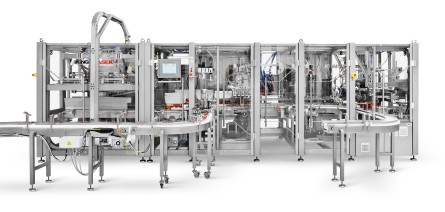

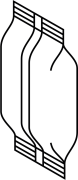

Vertical form-fill-seal (VFFS) machines represent the most widely used technology for bag packaging. The entire process takes place in one compact device – creating the packaging from flat film, filling it with the product, and then sealing it. Packaging on VFFS machines is fast, accurate, and highly efficient.

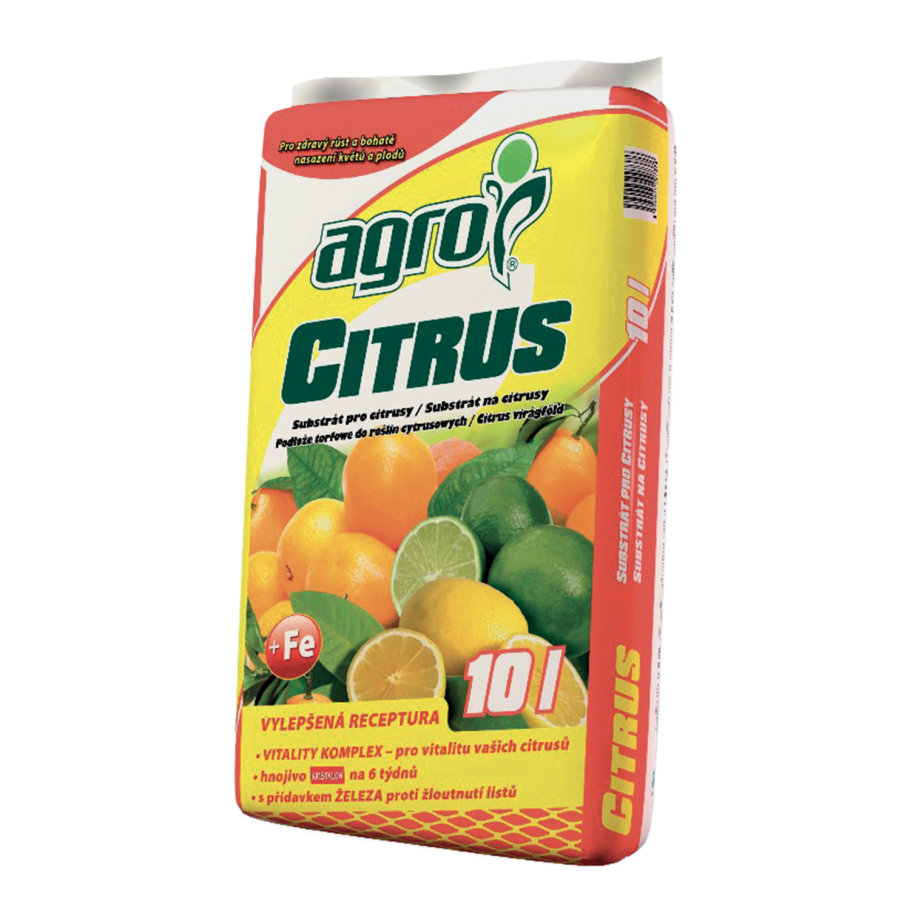

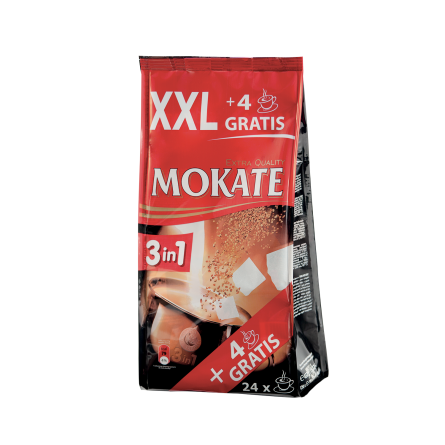

VFFS machines are used in a wide range of industries, from food and pharmaceuticals to industrial products. They can be adapted for different types of film, bag sizes, and dosing systems, including powders, granules, liquids, and solid products. Combining modern sensors, servo drives, and precise control, VFFS technology offers high performance, minimal waste, and long-term reliability—the ideal solution for any modern packaging line.