From precise filling to final cartoning – a single solution that combines performance, smoothness, and precise processing of each bag.

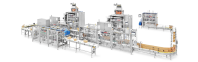

Viking Mašek designed and delivered a fully automated line for packaging legumes into brickpack bags. The solution combines precise dosing, bag forming, label application, and subsequent packaging into group cartons—all in one continuous production process.

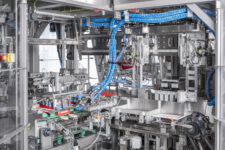

At the line entry point, there is a infeed conveyor that ensures an even supply of product to multihead combination weighers for precise dosing. The product is then packaged on an S300 vertical packaging machine, which produces a typical bag with clean edges and high stability.

The finished bags then pass through a TSH unit, which applies a resealable label – an ideal solution for products with repeated consumption, such as legumes. This is followed by transfer to a wrap-around cartoning machine, which completes the group packaging and ensures its strength and aesthetic appearance.

The entire line is synchronized and optimized for high performance, accuracy, and smooth production. The design allows for easy integration into other processes, such as palletizing.